AS 9100 Certification

Fast and Efficient Process

Highly Experienced Consultants

Servicing All Industries

Certification Guaranteed

AS9100 Accreditation

The Aerospace Quality Management Standard

AS9100 Rev. D, an international quality system standard for the aerospace industry (aviation, space and defence), includes the requirements of ISO 9001:2015 and additional critical aerospace requirements. Implementation of AS9100 can significantly benefit organisations seeking to secure aerospace contracts, improve internal processes, and expand services within the growing aerospace sector.

Clause 1 – Scope

Clause 2 – Normative References

Clause 3 – Terms and Definitions

Clause 4 – Context of the Organisation

Clause 1 outlines the requirements for a quality management system (QMS) in organisations that design, develop, or provide aviation, space, and defence products and services. It emphasises the need to consistently deliver products and services meeting customer, statutory, and regulatory requirements, with a focus on enhancing customer satisfaction and ensuring product safety.

Clause 2 lists the documents referenced within the AS9100 standard that are part of the certification requirements. These documents are essential for understanding and implementing the standard and provide additional guidance on specific needs for aerospace ISO certification.

Clause 3 provides a glossary of terms specific to the aerospace sector to ensure all parties have a consistent understanding. It includes industry-specific terms related to product safety, counterfeit parts, and special processes.

Clause 4 requires an organisation to understand the internal and external issues that can impact its QMS. This involves identifying the needs and expectations of interested parties, such as customers, suppliers, and regulatory bodies, and defining the scope of the QMS. It emphasises understanding the unique challenges and requirements of the aerospace industry.

Clause 5 – Leadership

Clause 6 – Planning

Clause 7 – Support

Clause 8 – Operation

Clause 5 emphasises the role of top management in demonstrating leadership and commitment to the QMS. Management must establish a quality policy and quality objectives that align with the strategic direction of the organisation. This clause also stresses the importance of fostering a culture of product safety and ethical behaviour.

Clause 6 involves planning for the QMS by addressing risks and opportunities that could affect its performance. Organisations must set quality objectives and plan actions to achieve these objectives. This clause emphasises risk management, particularly in areas critical to aerospace applications.

Clause 7 focuses on the resources needed to support the QMS, including human resources, infrastructure, and organisational knowledge. This clause also covers the control of documented information necessary for the QMS to function effectively. It emphasises the importance of maintaining special process capabilities and managing organisational knowledge in the aerospace context.

Clause 8 details the operational aspects of the QMS, including planning, implementing, and controlling processes to meet product and service requirements. This clause incorporates aerospace-specific requirements such as:

- Configuration management

- Product safety

- Prevention of counterfeit parts

- Enhanced focus on supplier management and traceability

- Control of special processes

It also covers design and development, production, delivery, and post-delivery activities with a heightened emphasis on aerospace industry needs.

Clause 9 – Performance Evaluation

Clause 10 – Improvement

Clause 9 involves monitoring, measurement, analysis, and evaluation of the QMS to determine its effectiveness. This includes conducting internal audits and management reviews to assess performance and identify areas for improvement. Organisations must also monitor customer satisfaction and evaluate the performance of external providers, which is crucial in the aerospace supply chain.

Clause 10 focuses on continuous improvement of the QMS. Organisations must identify and address nonconformities, take corrective actions, and continually improve the suitability, adequacy, and effectiveness of the QMS. This clause emphasises the need for a proactive approach to improvement, considering the high stakes involved in aerospace applications.

Comprehensive Advantages of Implementing AS9100

Implementing AS9100 offers extensive benefits to organisations in the aerospace industry:

Access to Aerospace Contracts

Essential for obtaining contracts in aircraft or spacecraft manufacturing, and a prerequisite for many original equipment manufacturers (OEMs).

Enhanced Quality Controls

Provides tighter controls than ISO 9001, focusing on product safety, counterfeit part control, and Foreign Object Debris (FOD) management.

Global Recognition

Increases your organisation's credibility and reputation internationally and domestically.

Compliance With Industry Best Practices

Ensures alignment with aerospace industry best practices, improving internal processes.

Customer Satisfaction and Confidence

Assures clients of the quality and safety of products, enhancing trust and customer satisfaction.

Supply Chain Access

Facilitates entry supplier information systems, boosting visibility in the aerospace supply chain.

Product Improvement

Focuses on continuous improvement of products and services, enhancing overall quality and reliability.

Process Effectiveness

Promotes effective and efficient business processes, leading to operational excellence.

Our 10-Step Process to AS9100 Certification

Our client-focused approach guarantees a thorough and effective AS9100 quality management system development through a structured 10-step process, utilising our specialised consulting services.

Tailoring your documentation to reflect your unique brand identity and operational practices, ensuring alignment with the AS9100 standard and the specific demands of the aerospace industry.

Our experienced consultants will perform an in-depth analysis of your organisation’s risks and opportunities to develop a tailored framework that meets the requirements of the AS9100 quality system.

Creating bespoke processes, policies, and procedures that not only meet your business goals but also adhere to regulatory standards and the rigorous criteria of AS9100 certification requirements.

Our dedicated team of consultants will guide you through each stage of the process, ensuring all procedures meet the strict standards of aerospace manufacturing certifications.

Delivering focused training to your team, our consulting services empower your staff to effectively apply new processes and maintain compliance with the AS9100 standard.

Deploying the AS9100 quality system and carrying out comprehensive evaluations to confirm adherence to the AS9100 standard and readiness for certification.

Identifying and rectifying any compliance issues to ensure your organisation fully meets requirements before proceeding to the certification phase.

Overseeing all elements of the audit, facilitating a streamlined and efficient process that aligns with best practices in aerospace certification consulting services.

Providing specialised support throughout the certification process, ensuring a positive outcome and helping you achieve AS9100 accreditation.

Establishing a comprehensive plan for the ongoing management, ensuring continuous improvement and sustained compliance with the AS9100 standard.

Testimonials

The process of ISO9001 certification was much easier than we anticipated due to engaging Scott as our consultant. Scott was fantastic to work with – he was confident, direct and focused on getting the job done. We interviewed a number of consultants before choosing Scott and he made us feel comfortable before and during the process. Scott did exactly what he said he would; he helped us through the entire process and ensured the audit ran smoothly. To top it all off, we gained certification over 1 month earlier than our deadline – a welcome bonus.

Haylee Evans

Operations and Financial AnalystWe engaged Scott to assist with the development of our safety, quality and environmental management systems from the ground up and through to full ISO certification. Scott’s approach was refreshing and the system we built together is both efficient and has significantly improved our daily practices. We look forward to continuing a long working relationship with Scott and S&J Auditing and Consulting.

Matt Lucarelli

Owner - Capstone ConstructionScott Smith at S&J Auditing and Consulting have implemented our HSEQ system here at Robowash which has helped our business immensely. Not only has the system allowed us to win and maintain contracts with pre-qualification being simplified, but it has given us a greater understanding of our system and processes allowing us to improve our business.

Jay Jasper

Managing DirectorS&J Auditing and Consulting have made it very easy for Mentis to obtain their ISO accreditation. Through Scott’s knowledge of the standards and his ability to understand our business, Scott was able to develop a quality system that suited Mentis in a timely manner and within budget. Mentis have also engaged SJ Auditing and Consulting to maintain the ISO system on a regular basis, this has helped Mentis become more efficient, by allowing staff to focus on their core tasks and still be connected to the quality process.

Dale Drazevich

Australian Managing Director

Over 80 5-star Google Reviews makes us the best choice for achieving AS 9100 Certification

Understanding AS9100

AS9100 is based on ISO 9001’s Quality Management System (QMS) requirements, specifically tailored for the aviation, space, and defence industries. It incorporates additional requirements, including project management, risk management, and control of counterfeit parts, focusing on product safety and ethical behaviour.

AS9100 vs. ISO 9001

While AS9100 follows the structure of ISO 9001, it includes additional aerospace-specific requirements. These additions cover areas such as project and risk management, product safety, and management of counterfeit parts, differentiating it significantly from ISO 9001.

Unlock new growth opportunities with AS9100 certification

it's ok , we don't like spam either!

Industries we serve with our AS9100 consulting services & beyond

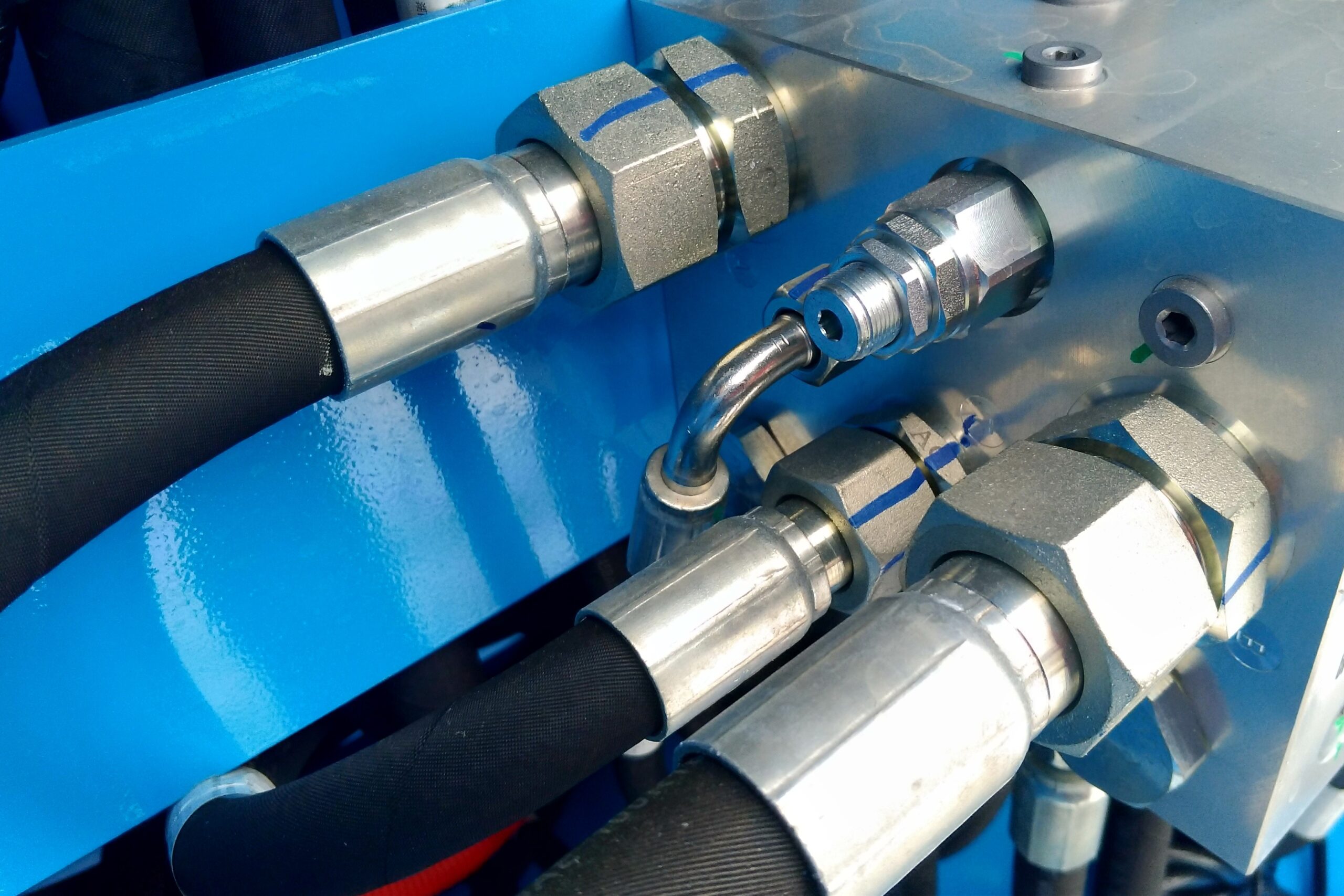

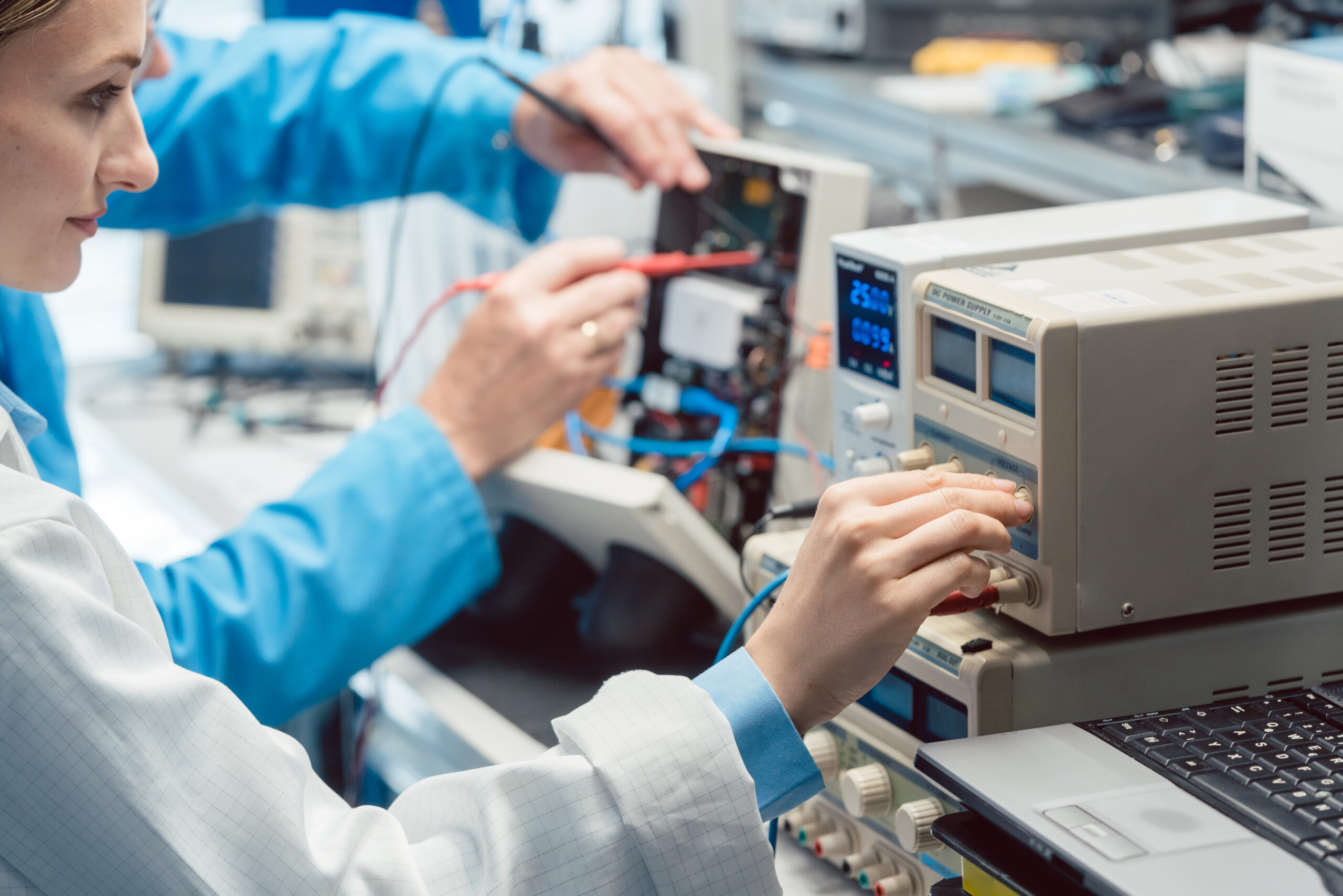

S & J Auditing and Consulting has extensive experience in sectors like manufacturing, construction, electrical services, logistics and aerospace. Our skilled consultants guide organisations through the AS9100 certification process, helping you establish a robust quality management system that meets all AS9100 requirements and enhances your operational standards. Explore the industries we’ve successfully supported below.

Learn more about out other certifications

ISO 9001

Quality Management Systems

ISO 14001

Environmental Management Systems

ISO 45001

Occupational Health & Safety Management Systems

ISO 17025

Accreditation & Certification for Laboratories

ISO/IEC 17024:2012

General Requirements for Bodies Operating Certification of Persons

ISO/IEC 17065:2012

Requirements for Bodies Certifying Products, Processes & Services

ISO/IEC 17034:2016

General Requirements for The Competence of Reference Material Producers

Start Your Journey with S & J Auditing and Consulting

Start your AS9100 certification journey with S & J Auditing and Consulting. Our team of AS9100 experts will help you optimise your quality management systems and ensure compliance with industry standards, guiding you through every step of the process.

Featured Case Studies

Read our case studies from some of WA & Australia’s most reputable companies.

Proudly trusted by

Frequently Asked Questions For AS9100

What is AS9100 certification?

AS 9100 certification establishes a standard for a quality management system specific to the aerospace industry. This industry-specific standard incorporates all ISO 9001 requirements alongside including additional quality and safety measures that relate to aerospace industries.

Who needs AS9100 certification?

Organisations within the aerospace sector, including manufacturers and suppliers of aerospace components and assemblies, need AS 9100 certification to demonstrate compliance with industry quality standards and improve their marketability. Manufacturers with AS9100 certification are more likely to appear reputable and receive tenders than manufacturers that aren’t accredited.

What are the benefits of obtaining AS9100 certification?

Obtaining AS9100 certification enhances a company’s reputation for quality and safety, increases customer trust, opens up market opportunities, and often also results in operational improvements that boost efficiency.

How long does it take to get AS9100 certified?

The time required to achieve AS9100 certification varies by organisation but generally takes between six to twelve months, depending on the size or scale of the company and the complexity of its organisational processes.

How much does AS9100 certification cost?

The cost of AS9100 certification varies depending on factors such as the size of the organisation, the complexity of its operations, and the chosen certification body. Costs include preparation, training, and the accreditation body’s fee for conducting an accreditation audit.

How often must AS9100 certification be renewed?

AS9100 certification must be renewed every three years, but it also requires annual surveillance audits to ensure ongoing compliance with the standard’s requirements between external audits for accreditation renewal.

What is the process for achieving AS9100 certification?

To achieve AS9100 certification, an organisation must implement a quality management system compliant with the AS 9100 standards, conduct internal audits to ensure the system is functioning properly, and then undergo a thorough audit by an accredited certification body. Upon passing this external accreditation audit, audited organisations then attain AS9100 certification through their accreditation body.